Our Flexitanks are meticulously designed to ensure reliability, durability, and food safety for transporting liquid products. Every component is crafted with precision to meet the rigorous demands of refrigerated and long-haul transport.

Technical

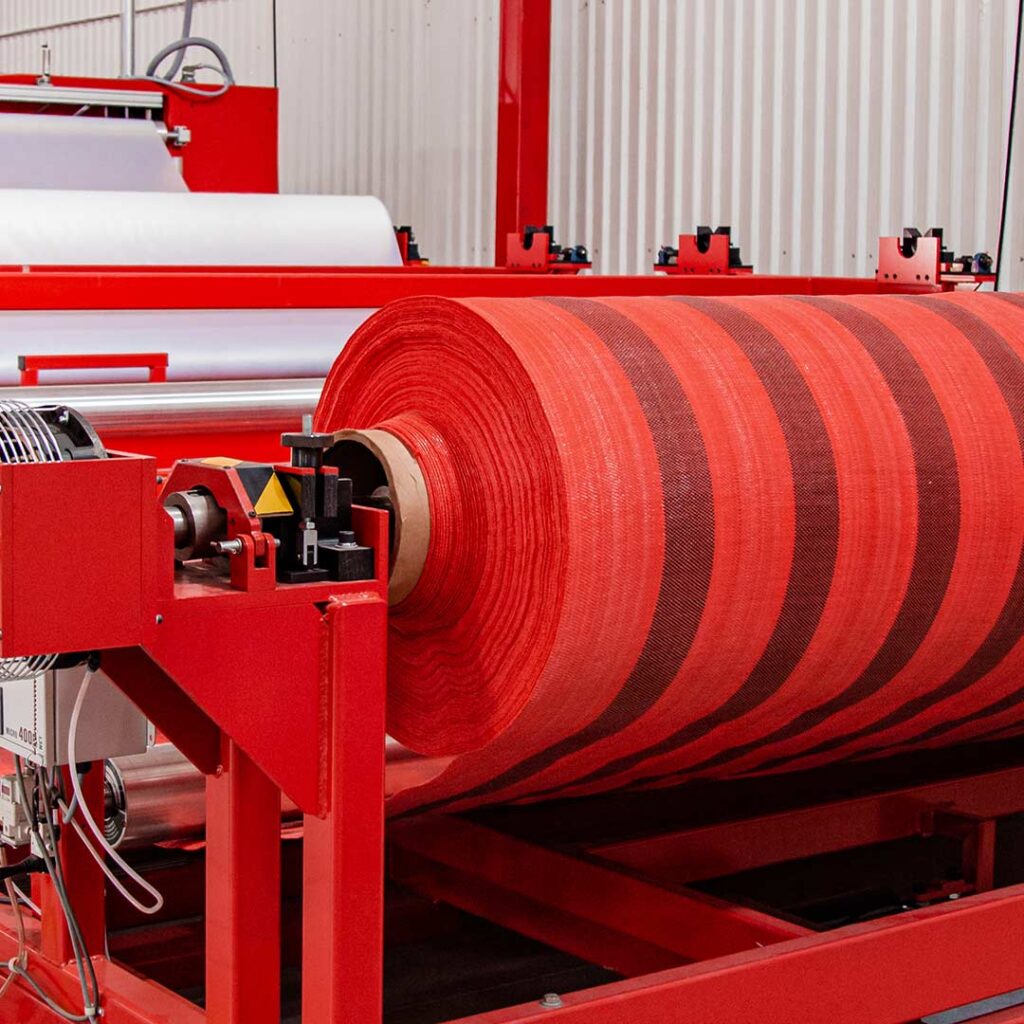

Material Composition:

- Inner Layer: Two layers of 300-micron high-density polyethylene (LLDPE) for superior strength and puncture resistance.

- Outer Layer: One layer of 270-gram woven polypropylene, providing robust support and ensuring compatibility with food-grade liquids.

Valve System:

Equipped with a 3-inch ball valve, our Flexitanks offer secure, efficient loading and unloading processes, minimizing product loss and contamination risks.

Engineered for Excellence

Advanced Manufacturing Technology

We employ state-of-the-art plastic welding technology to construct our Flexitanks. This advanced method ensures:

- Seam Integrity: Enhanced strength and durability to withstand the pressures of transport.

- Leak Prevention: Precise welds eliminate weak points, offering peace of mind during transit.

Food-Safe

Compliance

Our Flexitanks are designed to meet and exceed international food safety requirements. Certified for use with liquid food products, they are ideal for transporting temperature-sensitive dairy products and fruit juices, maintaining quality from start to finish.

Designed for Reefer Compatibility

Specifically tailored for use in refrigerated shipping containers and trailers, our Flexitanks ensure optimal temperature stability, protecting your liquid cargo during ocean and over-the-road transport.